Choosing between rotary compressors and reciprocating compressors depends on your specific application, air demand, budget, and maintenance needs. Here’s a detailed breakdown to help you decide:

⚙️ 1. Basic Working Principle

| Type | How It Works |

|---|---|

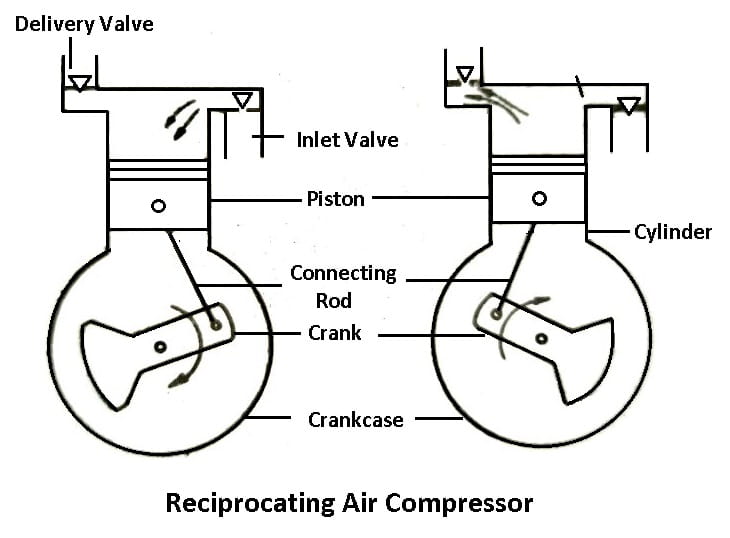

| Reciprocating Compressor | Uses a piston and cylinder arrangement. The piston moves back and forth (reciprocates) to compress air. |

| Rotary Compressor | Uses rotating elements (like screws, vanes, or scrolls) to compress air continuously and smoothly. |

⚡ 2. Performance & Air Delivery

| Aspect | Reciprocating | Rotary |

|---|---|---|

| Airflow | Pulsating — air delivery is intermittent. | Continuous and smooth airflow. |

| Pressure Range | Generally higher pressures (up to 250 psi or more). | Moderate pressures (up to 150 psi typical). |

| CFM (Air Volume) | Lower air volume, suitable for intermittent use. | Higher CFM output, ideal for continuous operation. |

🔊 3. Noise & Vibration

| Reciprocating | Rotary | |

|---|---|---|

| Noise Level | Noisy due to pistons and valves. | Quieter and smoother. |

| Vibration | Higher vibration. | Minimal vibration. |

🔧 4. Maintenance & Lifespan

| Reciprocating | Rotary | |

|---|---|---|

| Maintenance | Requires frequent maintenance (valves, piston rings, oil). | Low maintenance — fewer moving parts. |

| Durability | Good for intermittent, low-duty cycles. | Better for continuous, high-duty cycles. |

💰 5. Cost & Efficiency

| Reciprocating | Rotary | |

|---|---|---|

| Initial Cost | Lower upfront cost. | Higher upfront cost. |

| Operating Cost | Higher energy use due to heat and friction. | More energy-efficient and reliable long-term. |

| Efficiency | Drops at continuous loads. | Maintains efficiency under continuous load. |

🏭 6. Best Use Cases

| Application | Recommended Compressor |

|---|---|

| Small workshops, garages, home use | Reciprocating |

| Industrial plants, manufacturing, 24/7 operation | Rotary |

| Intermittent tool use (e.g., nail guns, paint sprayers) | Reciprocating |

| Continuous air supply (e.g., food processing, packaging, CNC machines) | Rotary |

✅ Summary: How to Choose

- Choose Reciprocating Compressor if:

- You need air intermittently.

- Your budget is limited.

- Noise and vibration aren’t major concerns.

- Choose Rotary Compressor if:

- You need a continuous and reliable air supply.

- Energy efficiency and low maintenance are priorities.

- You operate in an industrial or commercial environment.